European Union (English)

European Union (English)

Probably the best you can get

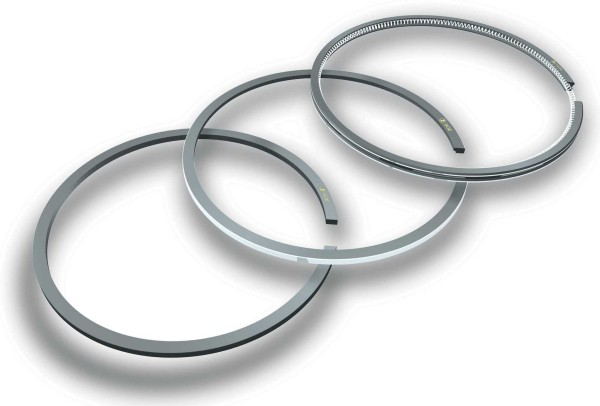

Goetze® is one of longest established names in the automotive industry, with a proud history of innovation dating back to 1887 which continues to this day. GOETZE piston rings are installed as Original Equipment for internal combustion engines and compressors on production lines throughout the world. Continuous collaboration with the design and test departments of virtually every engine and vehicle manufacturer, and development work and tests performed in our own test laboratories, provide comprehensive knowledge that can be utilized for almost all engines. This know-how and decades of experience with replacement piston rings are the basis of the individual design of every replacement ring set.

The design of Goetze piston rings is fundamentally based on the piston ring materials and running face coatings that have proven themselves in Original Equipment. Goetze’s innovative, OE-proven technologies such as Chrome Ceramic coatings (CKS®), Goetze Diamond Coating (GDC®) and LKZ® ensure not only the highest quality, but lower oil consumption, reduced emissions and increased durability.

Tenneco (Goetze’s parent company), is a Global OE piston rings and cylinder liner manufacturer, producing and delivering to OEM’s, the OE Spares market and the Aftermarket. We deliver Goetze parts to the majority of European engine manufacturers for light vehicle, commercial vehicle and industrial / off-highway applications.

Goetze products

- Piston rings

- Liners

Unique to the Goetze brand

- Innovative coating solutions such as CarboGlide and DuraGlide

- Unrivalled market coverage with over 1750 references*

- Comprehensive range including ring sets for Euro 6 compliant diesel engines and many new oversizes

- Technically advanced design, dedicated research and superior quality

- Goetze supplies a very large share of the demand for piston rings for new light vehicle direct injection diesel engines (up to 100% for some car makers)

- Strong OE coverage for all major European engine manufacturers

History

Founded by Friedrich Goetze, in 1887 in Burscheid, Germany. The company manufactured copper gaskets for steam valves. The company introduced Goetze piston rings, gaskets and seals and other products, building a reputation for quality throughout Germany. By 1912 the company was manufacturing piston rings for automobiles and aircraft engines. In the late 1940’s, post WWII Goetze expanded with joint ventures in Argentina, India, Brazil and France. In 1973, Goetze opened an R&D centre and focused on the development of new products and technologies. Throughout the next decades the company grew to be a key supplier of piston rings to the automotive industry.

Piston rings

The primary function of Piston Rings are:

- Seal the combustion chamber

- Support heat transfer from the piston to the cylinder wall

- Regulate the lubrication process

Pistons: piston rings and cylinder liners work together to provide a reliable seal in extremely aggressive conditions. To help cut emissions, they must be resistant to increasingly high temperatures and pressures, while minimizing friction and maintaining this high performance for longer than ever before. These exceptional demands require sophisticated materials engineering coupled with world class Research & Development expertise.

Technologies

CarboGlide® piston ring coating supports vehicle manufacturers’ efforts to make petrol engines more fuel-efficient. It cuts piston ring friction by up to 20% and improves fuel efficiency by up to 1.5% compared to conventional rings. Its high chemical and physical stability protect the cylinder bore surface from scuffing and scoring, especially under the most critical lubrication conditions. CarboGlide® is Goetze’s third and most advanced generation of ‘Diamond Like Coating’ (DLC) coated ring technology.

Goetze® LKZ-Ring® won a 2011 PACE Award. The innovative two-piece design originally was developed for highly-demanding diesel applications and now also optimized for direct injection petrol engines. Compared with the best conventional two-piece rings, the Goetze design reduces oil consumption by up to 50 percent and reduces friction by up to 15 percent.

Goetze LKZ ring

GDC : Goetze Diamond Coating :

With its Goetze-Diamond- Coating (GDC) system, Goetze developed a revolutionary coating based on diamond particle embedding. The first applications of the new coating were in passenger and commercial vehicle diesel engines, both of which went into production in 2004.

Diamond-Reinforced Ring Coating. The proven process of embedding particles in hard chromium provided the starting point for developing the new GDC coating system. Excellent process control during coating formation plus the exceptionally good anchoring of the embedded particles in the micro fissure network of the electroplated chromium layer were the basis for making the transition to an even harder surface. Ultra-fine diamonds with material specific, hybrid properties were chosen to increase the coating performance. Up to a temperature limit of around 500°C, the diamond particles result in a level of scuff and wear resistance that is considerably higher than that of chromium ceramic coatings.

Goetze Piston Rings – Quick look benefits

Market leading coverage

- Range of nearly 1800 part numbers covering 13.000 Tecdoc defined engines*

- Nearly 80%* coverage of circulating European Car Parc

Leading technology

- Unique technologies to improve durability & reduce emission

- OE Market leader

- Number 1 choice for European OEM’s

German OE supplier

- Engineered in Burscheid, Germany

Cylinder liners

Pistons, piston rings and cylinder liners work together to provide a reliable seal in extremely aggressive conditions. To help cut emissions, they must be resistant to increasingly high temperatures and pressures, while minimizing friction and maintaining this high performance for longer than ever before. These exceptional demands require sophisticated materials engineering coupled with world class Research & Development expertise.

Four main liner types

- Dry liner (D, DH)- no direct interface with the engine coolant system.

- Wet liner (WH) - direct interface with the engine coolant system

- Damp / hybrid liner (WH)

- Air-cooled barrels (DH)

Goetze Liners - Quick look benefits

Wide range - Over 360 part numbers

- Covering over 4200 engines

- 10.000 LV & CV applications

Chosen by OE

- Manufactured to tight tolerances from high strength material grades

Range now includes sealing rings and scraper rings (where applicable)

- These parts can be identified as beginning with “15-”

Find out more about our Engine Brands

Video

Downloads

Catalogue - Leaflets

Trouble Tracer

SEB – Service Engineering Bulletins

*Based on internal analysis of EU vehicle parc data Q4 2023

Scan to get more!

The content contained in this article is for informational purposes only and should not be used in lieu of seeking professional advice from a certified technician or mechanic. We are not liable for any damages resulting from your reliance on this content.

-piston-grooves-sb2123-1726566936793.jpg)