European Union (English)

European Union (English)

Beral has been supplying brake pads and linings to the commercial vehicle market for over 80 years. Its range of OE standard brake parts are designed specifically for each vehicle’s braking system.

Beral commercial vehicle brake parts offer the high levels of brake system integrity as well as reduced wear and extended life. Our commercial vehicle brake parts include more than 300 lining part numbers, 50 pad references and 130 brake discs, ensuring there is a BERAL part for almost every commercial vehicle in the marketplace, offering a leading coverage. Beral provides a full package of CV braking parts, including pads, linings, discs, wear-indicators, rivets and other accessories.

3 REASONS BERAL® BRAKE PADS & DISCS ARE GAME-CHANGERS

- Premium materials created to endure

- Ultimate disc-pad synergy for best-in-class performance

- Consistent stopping distance thanks to reliable performance

COUNT ON BERAL® STAY AHEAD OF THE COMPETITION

At BERAL®, we continuously develop new innovations to maintain powerful coverage of the CV market. From lab to real-life situations, BERAL® braking parts are specially designed to last longer, be more effective and most reliable. All so you can limit downtime, repair costs and ensure safety on the road at all times. As our tests show*, BERAL brake pads & discs can not only compete with current OE standards, but they also outperform competitors in the CV market. From leading-edge stopping distance to optimal wear resistance.

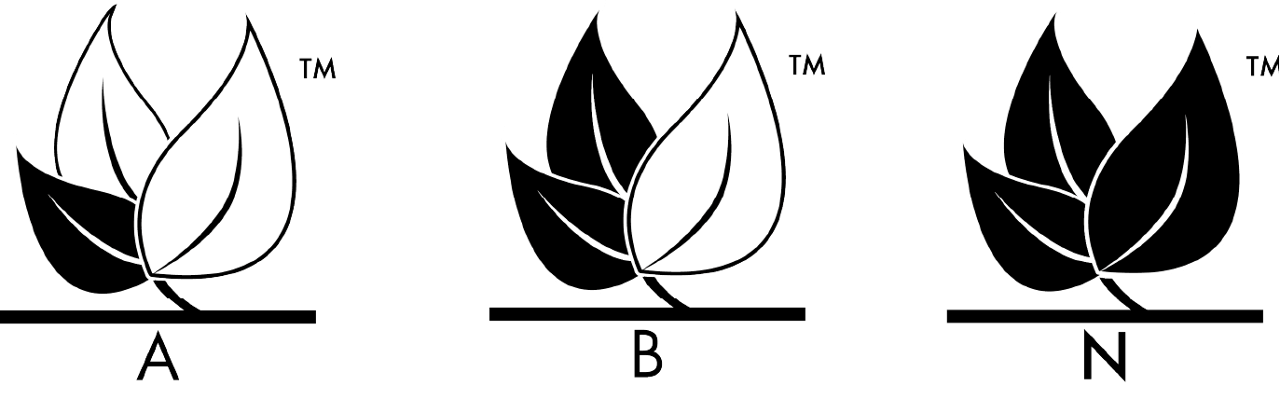

Copper free commercial vehicles brake pads

- A: This product meets the requirements for cadmium, chromium, lead, mercury and asbestos.

- B: This product meets the requirements for all level “A” metals as well as copper, brought down to under 5% of its content by weight.

- N: This product meets the “Zero- Copper” requirement with less than 0.5% of its weight made up of copper.

BERAL® is copper free. We were among the first manufacturers to offer copper free brake pads to customers for commercial vehicles. These copper free brake pads have achieved the N-leaf mark, indicating they contain less than 0.5% copper. By introducing the N-leaf mark into our commercial vehicles, we have achieved the best technologies and are in line with the strictest regulations. As such, BERAL is compliant with both US laws that as of January 2021 requires level B (less than 5% copper) and as of January 2025 requires level N (less than 0.5% copper).

Quickly find copper free brake pads

- Scan the box for the N-leaf mark

- Find the N21 marking on your brake pad

- Read the product specifications on TecDoc .

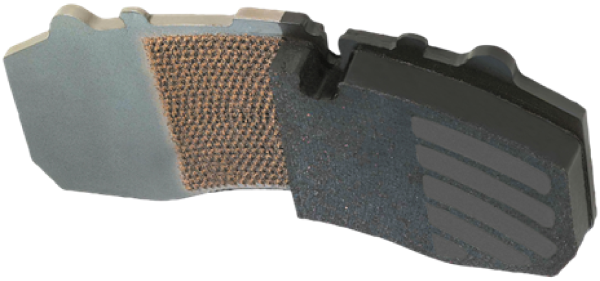

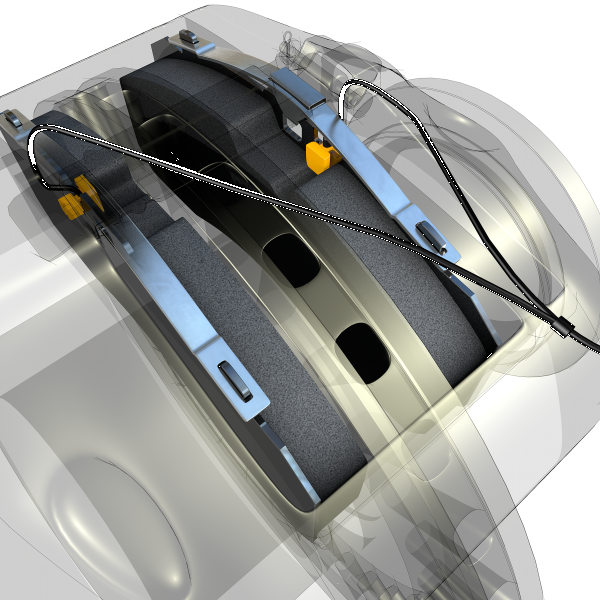

ProTec S®

When it comes to commercial vehicles, the safety of drivers and their cargo is a top priority. Even though brakes are arguably the most safety-critical component on any vehicle, they are also vulnerable to faults resulting from improper fitment. That is why BERAL® brings to market the innovative pad retaining system ProTec S® that Knorr-Bremse® has developed in conjunction with the foremost European commercial vehicle manufacturers. This clever technology ensures a permanent, welded connection between the spring and the brake pad backplate.

What‘s in it for you?

- The assurance of latest OE technology

- Quick, error-free installation

- More efficient braking

- Reduced brake noise and idle wear

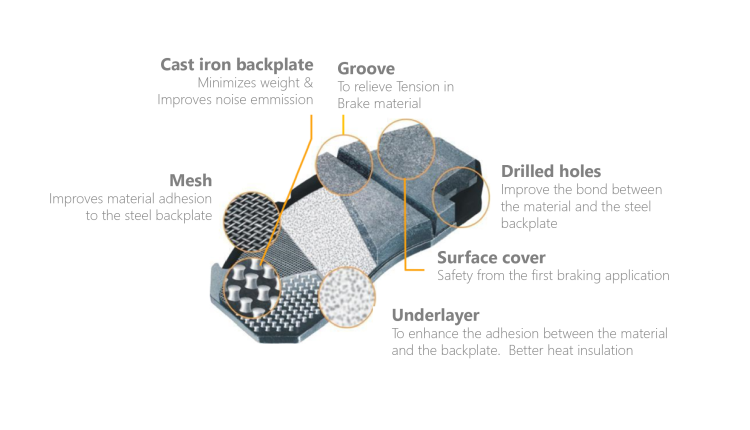

Metlock® & Greencoating

Metlock®

Bonding system for superior shearing resistance

Greencoating

Allowing initial high friction values from the very first-time brakes are used

Premium & OES – Technologies

Never settle for less when it comes to your safety

- The BERAL CV rotor range covers most of the popular vehicles on the road

- All references have high-quality materials and design, aligned to the latest technologies.

- Flexible, customer-oriented solutions

- Reliability linked to Tenneco’s full braking program

BERAL® brake rotors are only introduced after extensive testing to make sure of optimal performance in all situations. Make them your first choice.

PARTS SUITED FOR A WIDE RANGE OF APPLICATIONS: Trucks – Trailers – Buses - LCV.

CV Brake Linings

A wide range of over 300 linings are available from Beral, manufactured using moulded friction materials containing carefully selected friction modifiers and randomly dispersed reinforcing fibres in a phenolic matrix. For each of the linings a datasheet is available.

All types of driving conditions impose heavy demands on trucks and trailers. Both fleet owners and repair workshops share the same main concern: keeping each vehicle on the road, as long and as safe as possible, without unnecessary downtime. Quality and performance of braking parts is crucial, you need to be able to rely on linings for your truck, bus and trailer applications that are long lasting with excellent continuous performance. BERAL linings also stand out with their well-balanced drum wear, ensuring an even wear, an important combination to keep vehicles on the road.

WEAR INDICATORS – TRUST THE BEST FOR YOUR SAFETY

Beral offers a high-quality range of European made wear indicators ready to notify users when their brake pads and linings need replacing.

- Superior quality materials

- Sensor in fine materials tested to resist up to the heaviest conditions

- Kits including accessories following all OE requirements

- Superior performance in all conditions

- Dedicated references for both pads and linings

WHY BERAL – 8 REASONS TO CHOOSE BERAL

- Top class coverage

- OE quality materials

- Proven premium quality

- Superior safety and durability

- German heritage, R&D and production facilities

- Specific to application-friction materials

- Dedicated bus and coach friction materials

- Part of the DRiV family

DOWNLOADS

Leaflets

Trouble Tracer & Technical Tips

Catalogue & datasheets

New Part Information (NPI)

*Beral Test leaflet available on request: info@driv.com