United States (English)

United States (English)

Shopping Cart

Empty Cart

Part No: {{entry.product.code}}

Quantity: {{entry.quantity}}

Total {{cartInfo.totalPriceWithTax.value | currency:"$"}}

Total {{0 | currency:"$"}}

United States (English)

United States (English)

Part No: {{entry.product.code}}

Quantity: {{entry.quantity}}

Total {{cartInfo.totalPriceWithTax.value | currency:"$"}}

Total {{0 | currency:"$"}}

Asia Pacific

Europe, Middle East, Africa

România (Română)

România (Română)

European Union (English)

European Union (English)

België (Nederlands)

België (Nederlands)

Belgique (Français)

Belgique (Français)

France (Français)

France (Français)

Deutschland (Deutsch)

Deutschland (Deutsch)

Italia (Italiano)

Italia (Italiano)

Nederland (Nederlands)

Nederland (Nederlands)

Polska (polski)

Polska (polski)

Россия (русский)

Россия (русский)

South Africa (English)

South Africa (English)

España (Español)

España (Español)

Україна (українська)

Україна (українська)

United Kingdom (English)

United Kingdom (English)

Česko (Česká republika)

Česko (Česká republika)

United Arab Emirates (English)

United Arab Emirates (English)

North America

From ensuring that the air we breathe and the water we drink are clean, to searching for alternative energy sources, environmental concerns are a focus for many industries. The auto industry is no different. Whether it’s Tesla working on the next iteration of its electric car or parts manufacturers looking for ways to reduce their carbon footprint, ‘green’ advances are constantly being made.

This is especially true in the brake pad industry. Read on to learn about groundbreaking changes for brake pads. This evolution of brake pads signals a step forward for not only the environment but for performance and stopping power.

Historically, brake pads contained asbestos. Its strength, temperature and chemical resistance and low price made asbestos the go-to material for brake pad manufacturers. However, it was discovered that the dust generated by asbestos brake pads was hazardous to humans and the environment. By the 1980s, the hunt was on for less hazardous alternatives.

Semi-metallic and ceramic brake pads were developed to address these concerns while maintaining a high level of performance. Semi-metallic brake pads are made up of metal shavings (copper, brass and steel) held together with resin. Ceramic brake pads are the industry’s latest innovation. Using ceramic fibers and filling material, these brake pads can have a small amount of metal such as copper.

Copper is a popular component of brake pads thanks to its effectiveness in dissipating heat. Valued for its ability to deliver smooth braking, copper also helps reduce squeaking and shuddering. However, the copper used in brake pads has also become an environmental concern.

The issue of copper in brake pads first came to light in the 1990s, when cities in California were having trouble complying with requirements of the Clean Water Act that called for reducing the copper in the run-off going into San Francisco Bay. Studies showed that copper from brake pads was contributing to the problem.

Every time drivers would use their brakes, small amounts of copper would fall onto the pavement. When it would rain, the copper would get washed into the run-off, which then contaminated rivers, streams and lakes. Copper not only pollutes the water, it can have a detrimental effect on aquatic life including fish, amphibians and plants.

After much consideration, in 2010 the states of California and Washington passed the Better Brakes Law mandating a reduction in the amount of copper used in brake pads. Once brake pad manufacturers became aware of the legislation, they decided to reduce/phase out the copper in the brake pads they sell in all 50 states, making the California and Washington mandates the de facto law for the entire country.

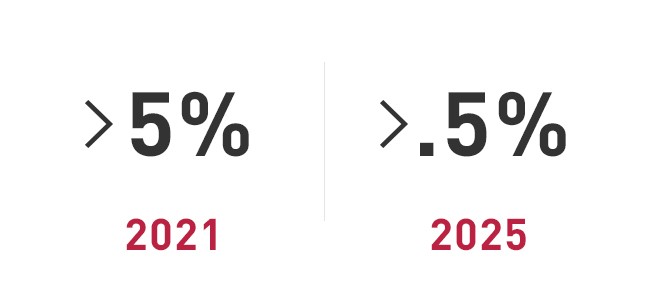

The law calls for brake pads manufactured after 2021 to contain less than 5% copper and by 2025, the percentage of copper allowed drops to a miniscule 0.5%. In addition, the use of other toxic metals and minerals including antimony, asbestos, chromium, lead, mercury and cadmium are being restricted.

Brake pad manufacturers have been working hard to meet these new standards. In fact, some brake pads on the market already meet the 2025 zero-copper standard. To achieve compliance, manufacturers are using a variety of approaches. Some are using alternative materials such as fiberglass, aramid and Kevlar, while others have made changes to the design of the brake pad to make up for the loss of copper.

Whatever approach is used, you can be sure that your new low-copper or zero-copper brake pads will perform as well or better than the old copper formulation. Your safety is of paramount concern to brake pad manufacturers.

To help customers find brake pads that meet the Better Brake standards, the Brake Manufacturers Council adopted the LeafMark. The darker the leaf, the higher the level of compliance the brake pad has achieved. Look for the LeafMark on the box, the next time you are shopping for brake pads.

Level A: Brake pad complies with requirements restricting use of cadmium, chromium, lead, mercury and asbestos.

Level B: Brake pad complies with restricting use of each of the Level A metals as well as copper, which must be reduced to less than 5% of material content by weight. Level B compliance is required by 2021.

Level N: Brake pad complies with the Zero-Copper mandate (less than 0.5% of total material content by weight) that takes effect in 2025.

Learn more about quality brake pads, find your car part, or find a local car repair shop today.

The content contained in this article is for entertainment and informational purposes only and should not be used in lieu of seeking professional advice from a certified technician or mechanic. We encourage you to consult with a certified technician or mechanic if you have specific questions or concerns relating to any of the topics covered herein. Under no circumstances will we be liable for any loss or damage caused by your reliance on any content.